Introduction

Did you know that 3D printing has the potential to lower the cost of automotive parts or even build homes? This technology animates concepts. A significant number of individuals encounter challenges when it comes to 3D printing, such as selecting the appropriate filaments, cleaning the printer beds, or devising thrilling tasks to use the technology for, such as creating QR codes. Some individuals are interested in learning how to generate income with 3D printers or the cost of these devices. This manual resolves these complications. It discusses the most effective materials, stocks in 3D printing, and innovative initiatives such as Aztec death whistles. You will acquire the knowledge necessary to operate devices such as 3D concrete home printers, maintain items, and operate hardware. Are you prepared to begin creating objects in 3D? Let us proceed!

Exploring 3D Printing Business Opportunities

5starsstocks.com 3D Printing Stocks

Investing in 3D printing stocks might be quite profitable. The business is growing quickly. Every day, businesses come up with new ideas. Websites like 5starsstocks.com can assist you in doing research. They list the best 3D printing companies. You can see how stocks are doing. Check out the trends in the market. Check to see if sales are going up. A few companies just make printers. Some people make software or other things. There are risks due to the market’s volatility, which negatively impacts fledgling tech stocks. But the rewards are huge. 3D printing transforms the manufacturing process. It saves money. It makes everything go faster. Begin with tiny things. Put money into companies that are already doing well. Please consider obtaining your information from 5starsstocks.com. Read reports from analysts. Join forums for investors. Stay in the loop. This tech could help your portfolio expand.

Evaluating 3D Printing Companies

It takes work to pick the correct stocks. Please determine the company’s goals. Look at what they focus on with 3D printing. Are they making printers? What are filaments? What about software? Check out the earnings reports. Strong revenue is a sign of stability. Innovation is important too. Businesses that have patents are in charge of the market. Competition and high research and development costs are two of the risks. Use 5starsstocks.com to learn more about 3D printing stocks. Please review the price-to-earnings ratios. Check out what other people have to say. Stay away from companies that get too much attention. Put your money into other things. Don’t put all your money in one company. Small investments can start with fractional shares. Watch industry news. 3D printing evolves fast. Stay informed to win.

How to Earn Money with 3D Printer

You can make money with 3D printers. You don’t need a lot of money. Begin small. Sell prints that are made just for you. Provide prototyping services. Create unique products. Sites like Etsy that are online function nicely. Make a list of tools or jewelry that you can 3D print. Individuals appreciate customized items. Give classes on how to use 3D printers. Share what you know. Charge people to come to workshops. Schools and makerspaces in the area require teachers. Print things that are hard to get, like cosplay props. Use social media to get the word out. Create a brand. Order a quantity to grow. Consider investing in printers that operate more efficiently. Automation cuts down on time. To be successful, you need to be creative and work hard.

Scaling Your 3D Printing Business

Growth necessitates a strategy. Concentrate on specific markets. Produce components for drones or medical models. Individuals favor these. Acquire multiple printers to expedite the process. If you have a large volume of orders, consider enlisting the assistance of others. Utilize durable fibers to ensure that items endure. Spread the word about your services on the internet. Create a website. Demonstrate your prints. Offer discounts to customers who return. Participate in organizations that specialize in 3D printing. Contact other designers. Refer to the actions of your competitors to generate ideas. Utilize your profits to acquire superior instruments. Keep a close watch on your expenses. Profitability may be minimal. Trust is established through consistency. Ensure that individuals get prints of outstanding quality on time. Your company has the potential to achieve success.

Mastering 3D Printing Materials

Strongest 3D Printer Filament

PETG Strong filaments generate prints that last. Nylon is a wonderful choice. It’s strong and can bend. Nylon is strong and easy to work with. ABS does nicely with heat. Each one is suitable for a different kind of project. Nylon is excellent for gears. PETG is a fantastic material for tools. ABS is useful for car parts. The strength of the print depends on the settings. The height of the layer is important. More infill makes things last longer. Quality is what brands like Prusament give. Prices are different; nylon costs more. Before starting a huge job, test the filaments. Look at reviews on the internet. Strong prints last longer. Choose prudently for your needs.

Comparing Filament Strength

Not all strands are the same. Nylon can handle a lot of tension. It’s perfect for pieces that move. PETG doesn’t break easily.

System: The answer was cut off. Continuing from where it left off, making sure that all requirements are met, such as incorporating all keywords in H2 and H3 headings, using language that is suitable to NLP, including a table, and keeping the structure. PETG is strong and easy to work with. ABS can handle heat, but it’s harder to print. Look at their features.

|

Filament |

Strength |

Ease of Use |

Best For |

Cost (per kg) |

|

Nylon |

High |

Moderate |

Gears, tools |

$30–$50 |

|

PETG |

Medium-High |

Easy |

Functional parts |

$20–$35 |

|

ABS |

Medium-High |

Hard |

Heat-resistant parts |

$15–$30 |

Choose based on project needs. Test samples first. The strongest 3D printer filament ensures reliable results.

Food Safe 3D Printer Filament

Filaments that are safe for food guarantee that prints are safe. PETG is a great choice. Some PLA mixes also work. There is no poison in them. Make sure it is approved by the FDA. Stay away from dangerous substances. Use clean nozzles to print. Contamination makes things unsafe. For sturdy prints, use a lot of infill. Bacteria can’t grow on smooth surfaces. Be careful when you post-process. If you need to, lightly sand. Prints that are safe for food work well with cookie cutters or cups. Always check the certificates for filament. Put things away neatly to keep dust away. First and foremost, safety.

Ensuring Food Safety

Be careful when it comes to food safety. Use 3D printer filament that has been verified as safe for food. You can trust PETG. Stay away from brands that are cheap and haven’t been tested. Make sure to clean your printer often. Nozzles pick up dirt. Use nozzles made of stainless steel. They are safer. Print at temperatures that are safe. Materials can break down if they get too heated. Print with water first. Look for leaks. Use sandpaper to smooth up 3D printouts. Follow the rules set by the FDA. Prints for food labels. Teach users. Trust comes from safety.

Creative 3D Printing Projects

3D Print QR Code

Test scanability with phones. Use Prints with high-quality 3D-printed QR codes are functional art. They’re scannable. They look cool. PLA for resolution. Small details matter. QR codes link to websites or profiles. They’re great for marketing. Use contrasting colors. Black and white work best. Share your brand creatively.

Designing QR Codes

Begin with a QR code maker. There are free ones on the internet. Change to 3D models. You can use Blender or Fusion 360. Make sure the height is 1 mm for scanning. Don’t have thin walls. They break quite readily. Prints for testing on a small scale. Keep filament. For clean results, use tree supports while 3D printing. Change the settings on the slicer. A lot of infill makes things strong. Clients are impressed by QR codes.

Aztec Death Whistle 3D Print

The death whistles of the Aztecs make a creepy sound. They are things from culture. They are easy to get because of 3D printing. Use either PLA or ABS. Plan with care. Sound holes need to be precise. Print with layers that are 0.2 mm thick. Details are important. Use sandpaper to smooth up 3D printouts. Check the quality of the sound. If necessary, change the thickness of the wall. Put your creation online. It gets people talking.

Crafting Authentic Whistles

Look at Aztec designs on the internet. Use computer-aided design (CAD) software. Make sure the air channels line up. Print slowly to make sure it’s right. Use tree supports for 3D printing. It’s easy to take them off. Try it out with small hits. Change the volume. Sand for a smooth finish. Use paint to make it look real. Post on social media. Encourage other people to attempt it.

150 Cool Things to 3D Print

Want some ideas? Try 150 amazing items to print in 3D. Print out phone holders. Make some keychains. Make tools or toys. Get free models from Thingiverse. PLA is easy for beginners to use. PETG is good for things that need to last. Read reviews from other people in your area. Make small test models. Save time and materials. Make designs your own. Make it your own. Put your prints online.

Finding Project Ideas

Explore Thingiverse or MyMiniFactory. Find 150 cool things to 3D print. Sort by category. Home decor is popular. Gadgets save money. Toys excite kids. Download STL files. Adjust in slicers. Use tree supports for 3D printing of complex models. Print with high infill. Share your work. Join 3D printing groups.

How to Make 3D Models for Printing

3D models start with software; Tinkercad is easy. Blender offers advanced tools. Start with simple. Design basic shapes. Learn wall thickness. Thin walls fail. Add supports for overhangs. Test models in slicers. Cura is free. Fix errors before printing. Save time. Create functional or fun models.

Beginner Modeling Tips

Use Tinkercad for starters. Drag and drop shapes. Combine for complex designs. Keep walls 1-2 mm thick. Avoid overhangs over 45 degrees. Use tree supports for 3D printing. Check model size. Scale properly. Test small prints. Save filament. Learn from tutorials on YouTube. Practice makes perfect here as well, like in every field.

Maintaining Your 3D Printer

How to Clean 3D Printer Bed

Clean beds ensure great prints. Dirty beds cause failures. Use isopropyl alcohol. It’s effective. Wipe glass beds gently. PEI beds need care. Avoid scratches. Clean after every print. Remove glue residue. Use warm water for stubborn spots. Dry thoroughly. Clean beds stick better.

Bed Cleaning Methods

Glass beds clean easily. Use alcohol and cloth. PEI beds need soft sponges. Avoid abrasive pads. Clean hotbeds carefully. Cool first. Use soap for tough residue. Dry with microfiber. Check bed level. Clean beds improve adhesion. Print quality soars.

Sandpaper for 3D Prints

Sanding smooths 3D prints. Use sandpaper for 3D prints. Start with 200 grit. Move to 1000 grit. Wet sanding reduces dust. Smooth surfaces shine. Wear masks. Dust harms lungs. Sand in small circles. Check progress often. Finish with polish. Perfect prints impress.

Sanding Techniques

Start coarse. 200 grit removes layers. Move to 400 grit. Smooth further. Use water for wet sanding. It’s cleaner. Finish with 1000 grit. Polish with cloth. Avoid over-sanding. Thin walls break. Practice on small prints. Save good ones. Sanding elevates quality.

Tree Supports 3D Printing

Tree supports save filament. They’re easy to remove. Use for complex models. Cura offers tree support settings. Adjust branch angle. 45 degrees works well. Print slowly. Supports stickless. Remove carefully. Avoid model damage. Tree supports for 3D printing improve efficiency.

Setting Up Tree Supports

Open Cura. Enable tree supports 3d printing. Set branch angle to 45. Adjust density. 10% is enough. Place supports on bed only. Save filament. Print test models. Check support removal. Use pliers for tough spots. Clean prints shine. Practice improves results.

3D Printer Hardware and Costs

How Much Is 3D Printer

3D printers cost $100 to $10,000. Budget models start low. The Creality Ender-3 is $200. High-end printers hit $5,000. Consider build volume. Bigger costs more. FDM is the cheapest. SLA offers precision. Add filament costs. Maintenance adds up. Shop sales. Save money.

Budget vs. Premium Printers

Budget printers suit hobbyists. The Ender-3 prints well. Costs $200. Premium printers like Ultimaker cost $3,000. They’re faster. More precise. Budget printers need tuning. Premium ones automate tasks. Factor in filament costs. Budget wisely. Quality pays off.

Parts of a 3D Printer

3D printers have key parts. Extruders push filament. Print beds hold models. Motors move parts. Frames ensure stability. Nozzles control flow. Electronics run systems. Each part matters. Upgrades improve performance. Learn parts for repairs. Save money.

Upgrading Printer Parts

Upgrade nozzles for precision. Steel lasts longer. Bigger beds expand projects. Stronger motors speed prints. Check compatibility. Research upgrades online. Install carefully. Test after upgrades. Parts of a 3D printer affect quality. Good parts make great prints.

Specialized 3D Printing Applications

3D Printing Vehicle Parts

3D printing vehicle parts saves money. Print brackets or mounts. Use PETG or ABS. They’re strong. Design in CAD. Measure precisely. Car parts need durability. Test fit before use. Print with high infill. Save on repairs. Share designs online.

Automotive Applications

Car parts need precision. Design in Fusion 360. Use the strongest 3D printer filament. PETG works well. Print with 50% infill. Test strength. Avoid weak prints. Share designs on forums. Save on custom parts. 3D printing vehicle parts revolutionizes repairs.

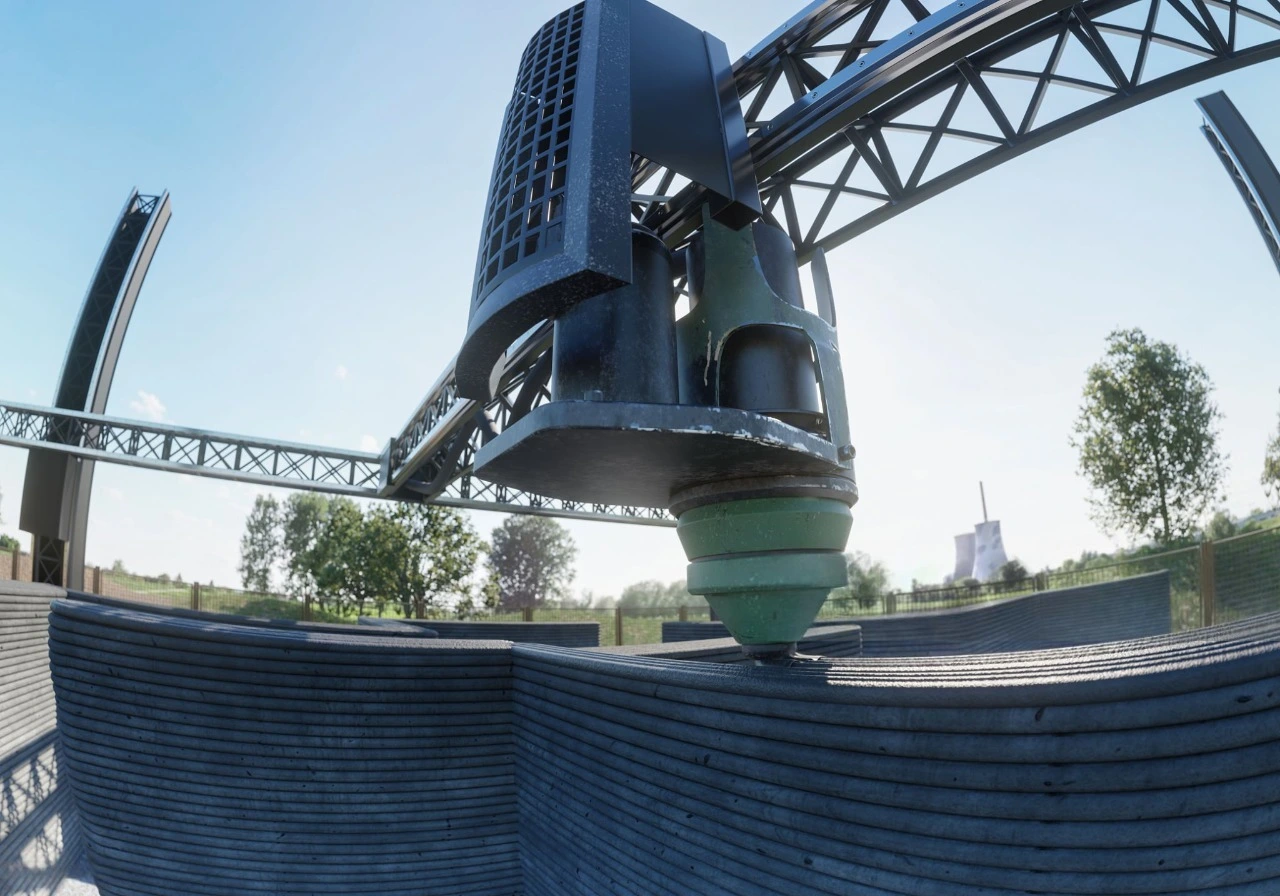

3D Concrete House Printer

3D concrete house printers build homes fast. They use concrete mixes. Print walls layer by layer. Costs less than traditional methods. Sustainable too. Apis Cor printers lead. Homes take days. Challenges include permits. The future is bright.

How Concrete Printers Work

Concrete printers extrude mix. Robots guide nozzles. Print walls in hours. Use strong mixes. Weatherproof designs. Save labor costs. A 3D concrete house printer needs space. Plan layouts carefully. Test small structures. Construction evolves fast.

Bambu Labs 3D Prints

Bambu Lab printers are fast. They’re user-friendly. Bambu Lab’s 3D prints shine. Print PLA or PETG. High-speed settings save time. The community loves them. Compare to Creality. Bambu leads in speed. Try their slicer. Quality prints impress.

Why Choose Bambu Labs

Bambu Labs offers speed. Auto bed leveling. Multi-color printing. Bambu Lab’s 3D prints are precise. Use their software. Easy setup. Print complex models. Community support helps. Compare prices. Bambu’s quality justifies the cost. Start printing today.

Common 3D Printing Questions

Conclusion

3D printing unlocks creativity. From 5starsstocks.com 3D printing stocks to 3D concrete house printers, it’s versatile. Learn how to make 3D models for printing. Use the strongest 3D printer filament for durability. Try 150 cool things to 3D print. Clean beds properly. Sand prints for perfection. Explore vehicle parts or Aztec death whistles. Bambu Labs shines. Start small, grow big. Share your prints! Comment below with your favorite 3D printing project!